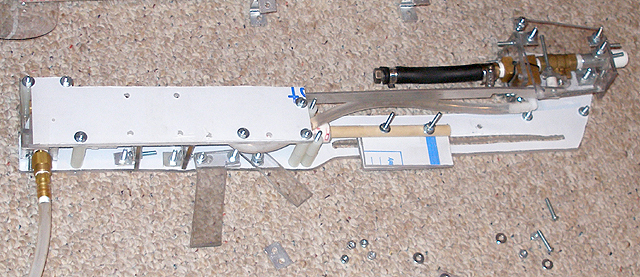

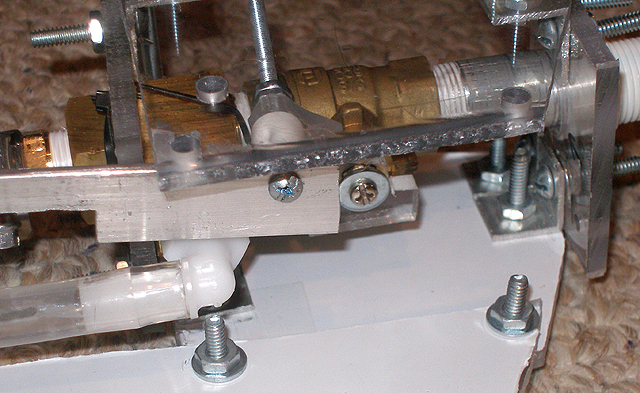

I call it a prototype because it's imperfect and I used it to get the bugs out of the design. From all the pictures, you see that I drilled more holes than needed, and that many of the screws are too long. We're improving homemades, but it only happens step by step.

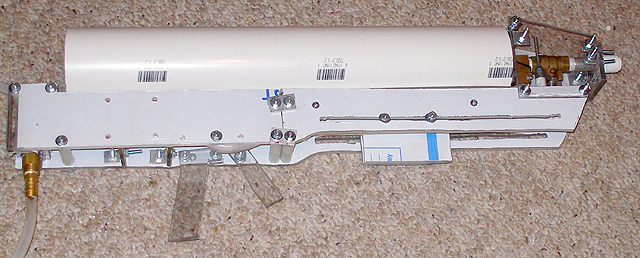

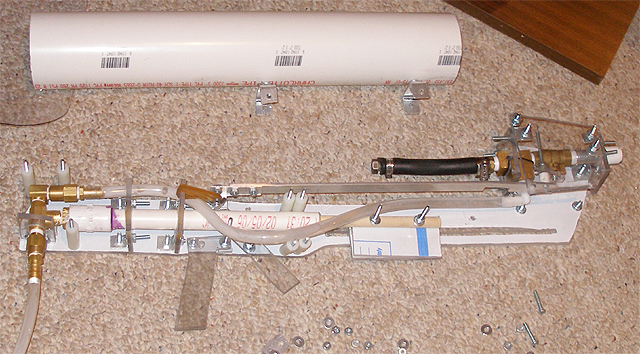

Riptide leaps ahead. It sports a trigger, tracked pump, and casing. The casing contains all the parts and differs from the casing style I tried in DR-3. In DR-3, I tried to hard to copy the style of many Nerf designs, and forgot that those designs need not fit pressurized parts. Here, I returned to form with plates that sandwich the parts, like my water balloon launcher. I've yet to remove all the paper off the plastic, which comes with the paper attached and is compliments of Ben (thanks Ben). The plastic is clear. I didn't want to take the whole thing apart now, so I left the paper on.

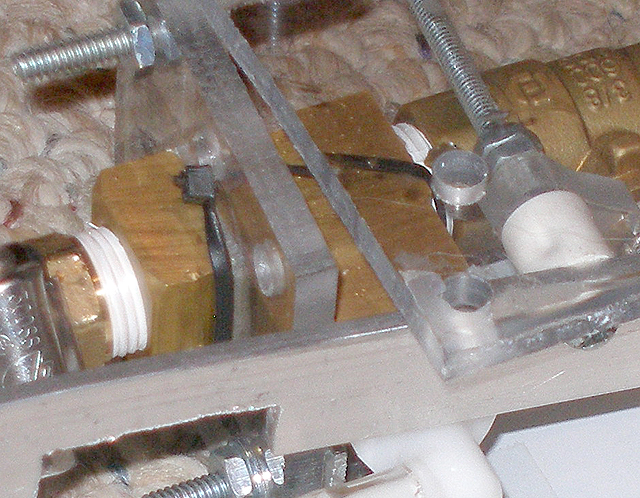

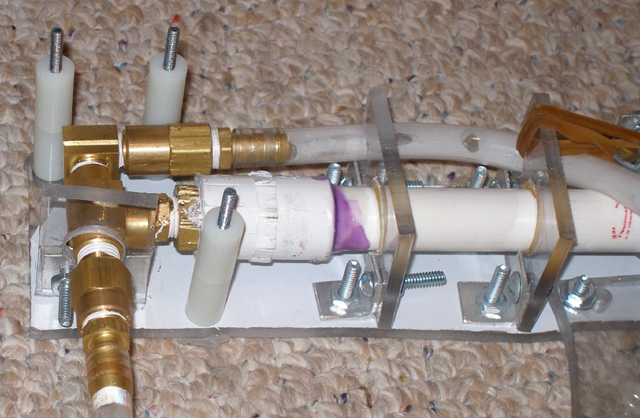

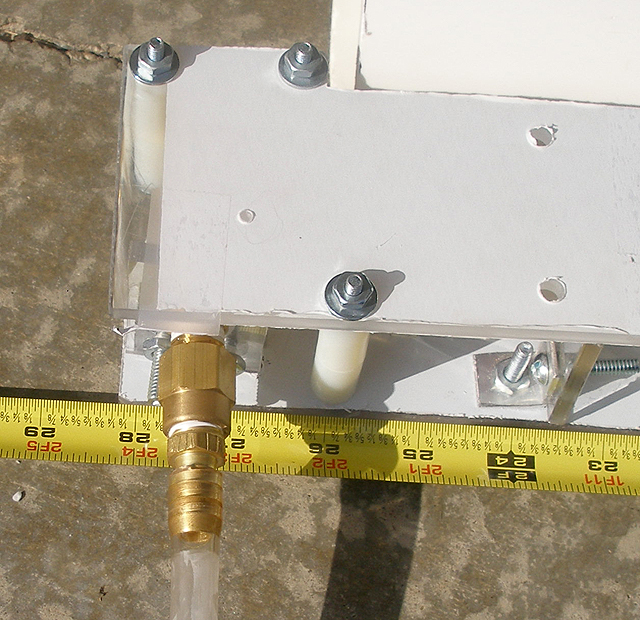

I used all brass parts. Brass weighs less than steel and occupies less space than PVC. I placed all the check valves at the end of the pump; and I admit I stole this directly from Hasbro's design. It's a nice convenience.

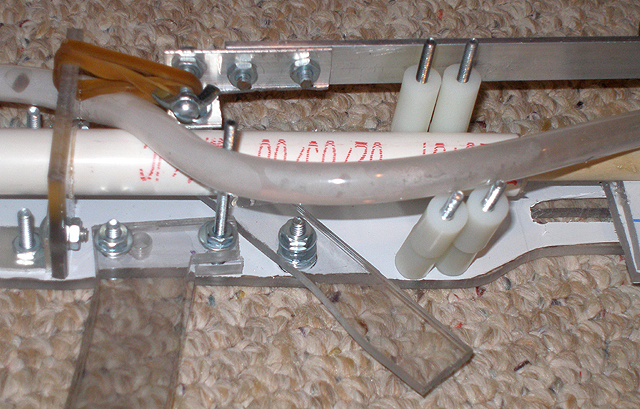

Plastic sheets with holes in them suspend the parts within the gun, keeping the parts from moving. The inside structures let me weave other parts (mostly the vinyl tubing) around them. I secured the plates with bolts, and spaced them with nylon spacers.

The pump differs from my previous pump. I used two rubber grommets, screwed them into the end of a dowel. I don't have pictures of this, but will get some soon.

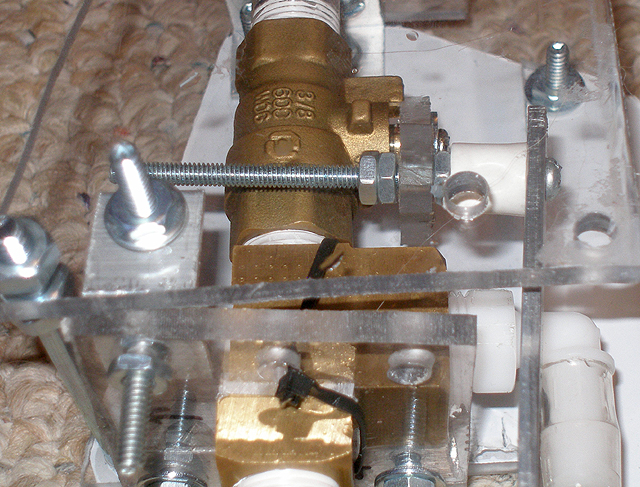

After much thought, I realized that a rotary trigger results in more displacement for less space. This trigger pushes on the aluminum beam, pushing open the valve. Most valves you pull open; this one you push open. When you release the trigger, the rubber bands pull back on the aluminum rod, closing the valve and returning the trigger--a nice setup.

The valve is a 3/8" brass ball valve. This valve opens with little force, and my longer torque arm opens it fully without hassle. The aluminum beam connects through a bolt to the arm, and pushes it forward to open the valve.

I ordered a special brass tee off McMaster, the one you see best in the overall internals picture. It has a square exterior, which means that since I cut a square whole for it to fit it, it won't rotate like circular parts. It also saves space.

The pipe nipple is aluminum.

The gun is 28 inches long from nozzle to end. It weight roughly 7 pounds too, but that's only because I used 3" schedule 40 PVC for the pressure chamber casing. Once I switch to cellular-core pipe, it'll be less, likely around 6 pounds.

The trigger system works well. This video shows that you can do pulse shots easily. I apologize for the low quality and the big size (33 megs); I can't resize it.

I only used one nozzle, a sixteenth inch one, and it got about 36 feet in range. I haven't done any other testing yet, and I suspect that that nozzle range's was less than optimal.

Questions, criticisms, compliments, extra posts--all are welcome.