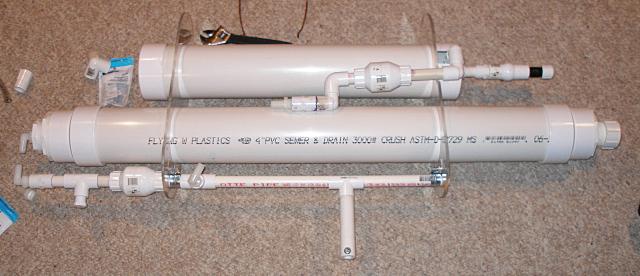

The gun's going to be called THR (Tactical High Range water gun). This is my response to some shortcomings people have seen in my homemade water guns. Specifically, it's a response to the lack of an included reservoir. This is just what I've completed today, so it's far from complete. You can get the basic gist of the design from the image above, but it has nothing showing the pump system, the handle, the strap, the nozzle selector, etc. The innovation here is the use of a plexiglass structure, which allows different designs with a lot of structural stability at a low weight. Okay, maybe it's not an innovation because I got the idea from Lonnie Johnson's prototype Super Soaker.

The plexiglass is nice because it allows for a lot of water storage without the gun changing into hard to hold shapes or the gun getting wider. Basically, this gun will be easy to hold because it's just two pipes with one on top of the other. That was one reason I never made a gun with an included reservoir, but now I think I have the answer.

Powering this water gun will be a very thick CPS chamber that should easily reach 55 feet effective range, if not more. Combine that with a big PC and big water capacity, and this gun will last a while.

I'm experimenting with water reservoir lengths and pump lengths. I'm going to start long and see how I like both. Right now the reservoir is 36 inches of 4 inch drain pipe, which is about 7.4 L. The pump I plan to start at 18 inches, which is 60 mL. The cool thing about this design is that it uses long lengths of pipe in a way that nearly any size water gun is possible. If I decide this one is too long, I can shorten it without redoing the entire water gun. Very cool.

I'm lucky to have not very cold weather right now, I guess. Not everyone can work on water guns at the moment.

I'm really liking how it's turned out so far. For an hour or two of work, it's great. Most of the time was spent using a router to cut the plexiglass and sanding it smooth afterward. After that I just had to cut the pipe and plug some PVC together to get what you see. I've walked around with it and it seems easy to hold and light. Using PVC drain pipe was a good idea. This water gun is strong, but very light.

For those interested, this gun will not be on SSC immediately after we update. I'd like to save this for a later update. It's non-essential to the major update in my mind.